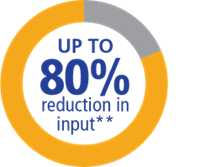

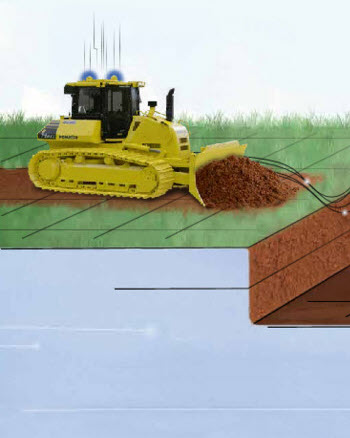

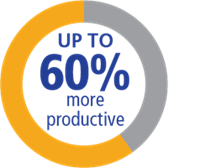

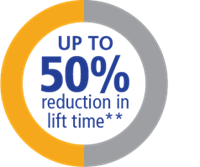

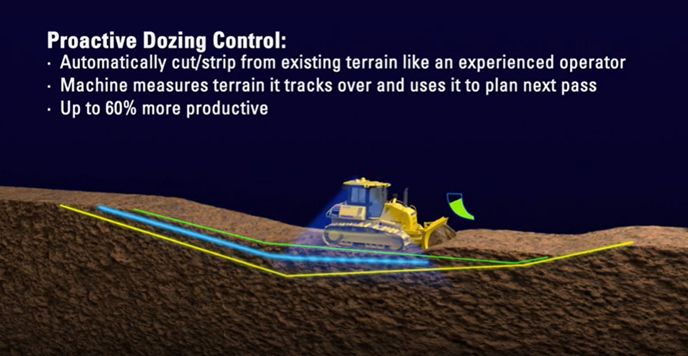

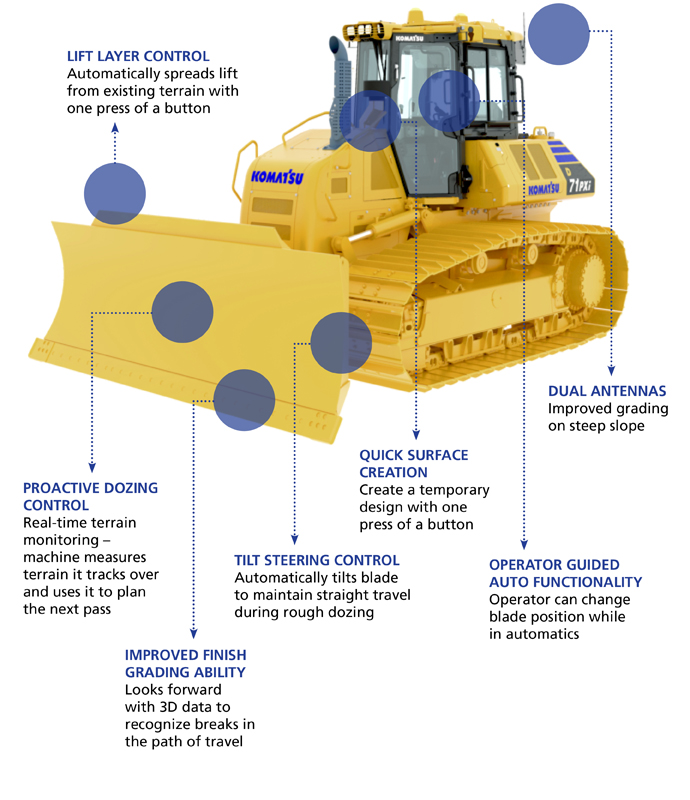

To pursue maximum productivity at your job site, you need to plan your work, and then work your plan. With intelligent Machine Control dozers, you can work your plan with efficiency and accuracy. Through automatic dozing, IMC-equipped machines help you make every pass count –from rough cut to finish grade.

Call Now Request More Information

.jpg)