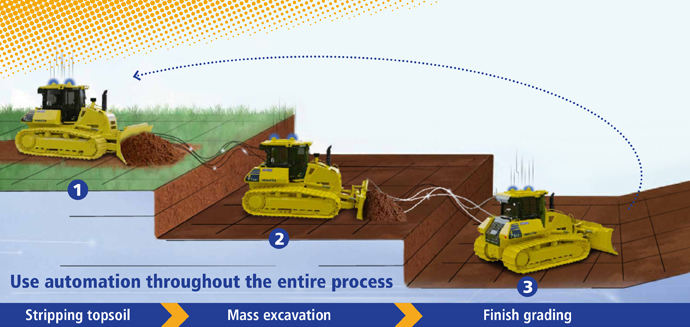

Your job site just got even smarter with Komatsu Intelligent Machine Control 2.0, now available on excavators and dozers.

Transform your job sites into highly efficient, highly productive operations by taking advantage of productivity-enhancing automation and cutting-edge job design.

Benefits of Intelligent Machine Control 2.0 include:

- Getting new operators up to speed quickly

- Going from mass excavation to finished grading faster than ever

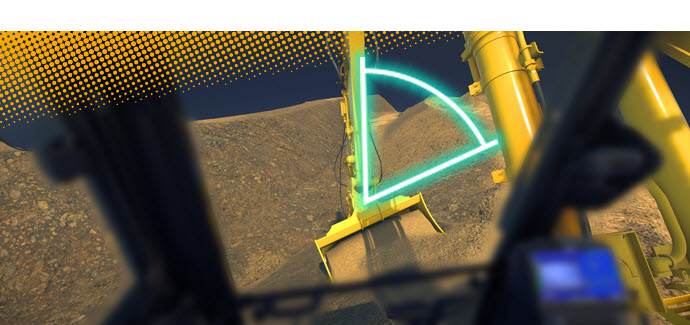

- Fully integrate 3D design data into your machines

- Empower operators to work efficiently, pass after pass

Talk to our SMART Construction experts about how the new Komatsu IMC 2.0 can deliver higher levels of productivity.

Call Us Request More Info

_1.jpg)