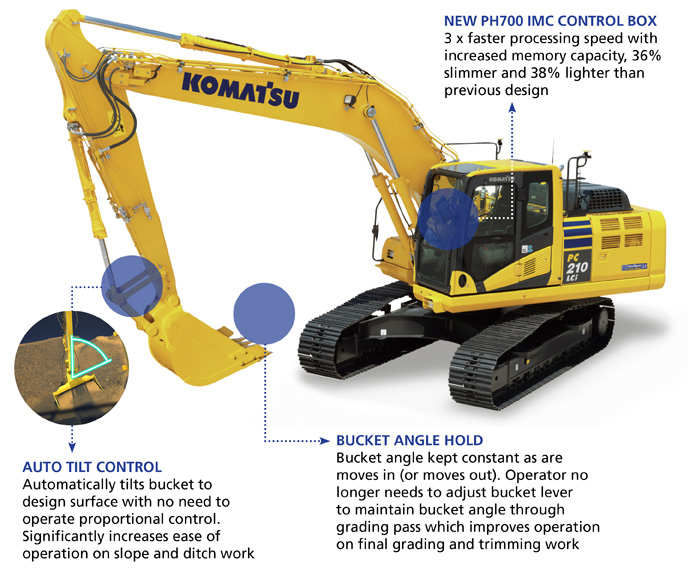

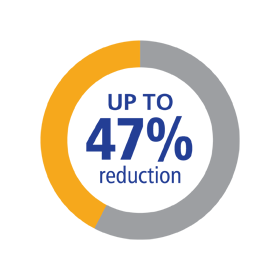

Using Komatsu’s innovative Intelligent Machine Control (IMC), you can program 3D design data directly into your machines. Your operators, regardless of their experience, can work with outmost efficiency, guided by sophisticated automation. You can be confident you’re getting the most from your machines, your crew, and your carefully designed plan.

Talk to our SMART Construction experts about how the new Komatsu IMC Excavators can deliver higher levels of productivity.

Contact Us Call 1-866-458-0101

-(1).jpg)

.png)

.png)

.png)