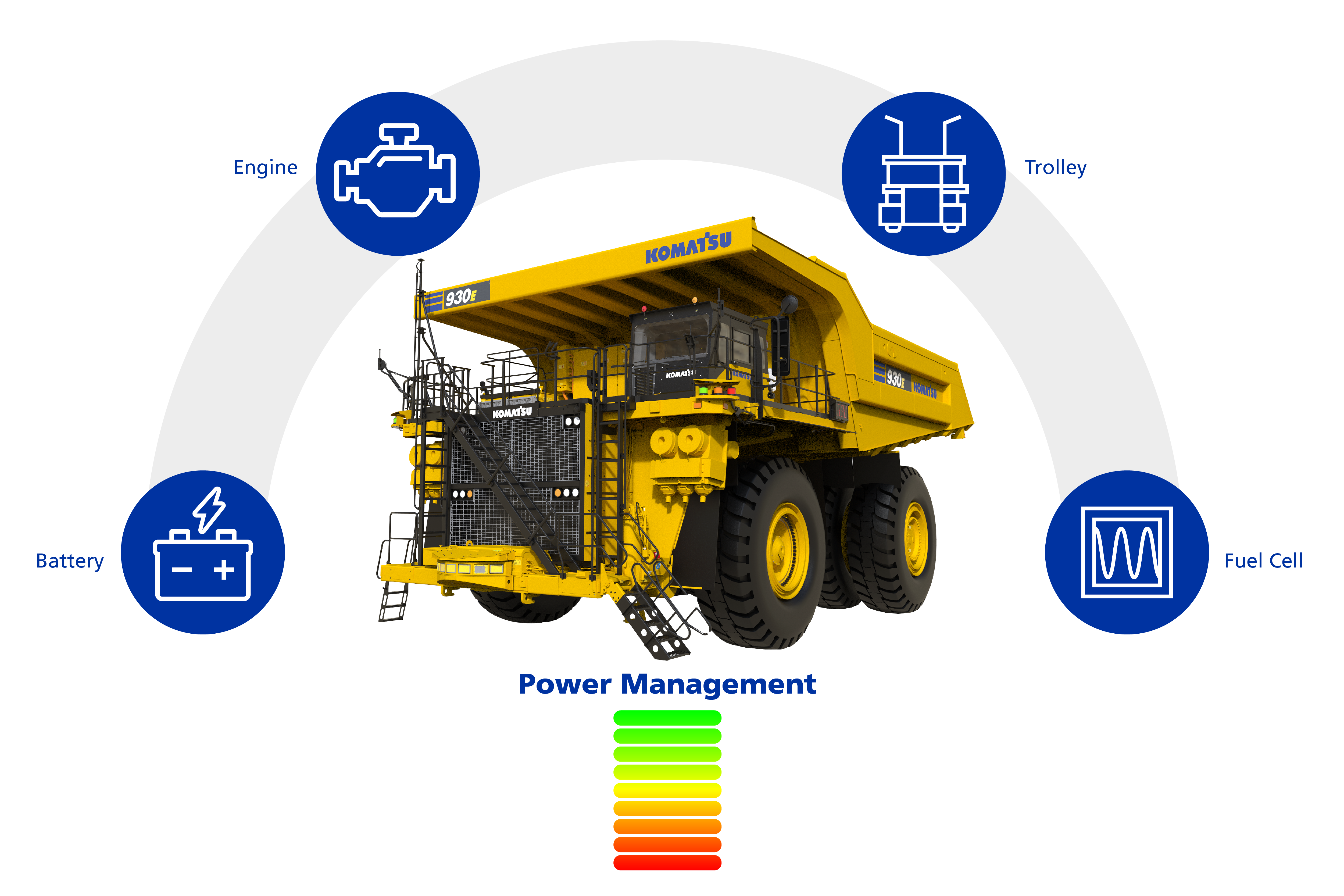

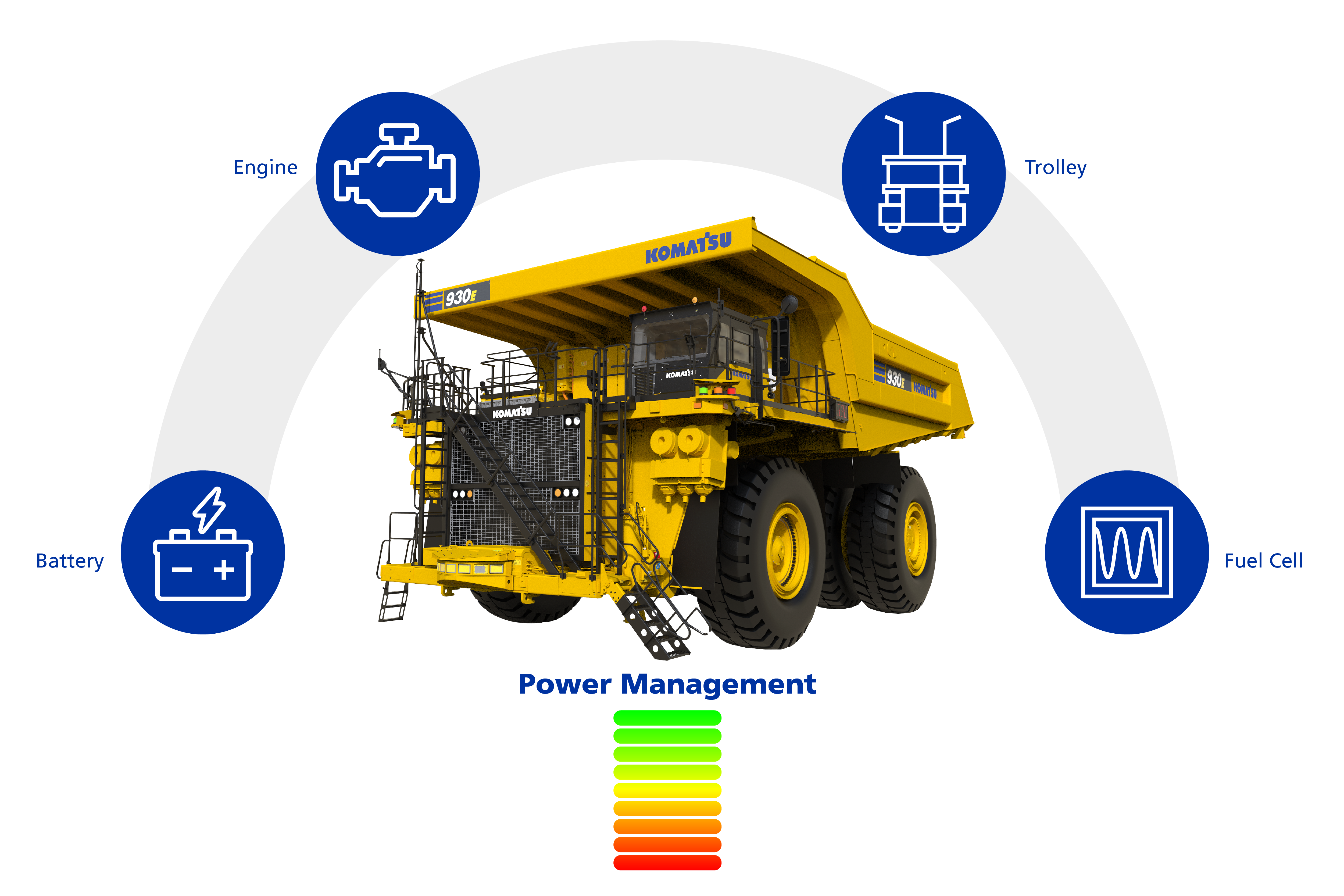

Dillon: Komatsu recently announced its

Power Agnostic Platform at the Mining Expo, and that's exciting. They're developing a next-generation haul truck with a conventional diesel engine that has the potential to run on HVO but will easily adapt to other energy sources later. So instead of getting a remanufactured diesel, you could put in a battery pack that uses the latest technology. Also, if a mine gets developed over several years and has the ramps in place and the links required for trolley assist, they can add a

trolley system to that truck, supporting electrification.

The idea is that if you purchase a truck today, it's future-proofed. As new technologies become available, you can adopt them without reinvesting in another significant asset.

Cummins, another one of our partners, is also on a journey for sustainable mining solutions. Even though they were born on diesel and are over 100 years old, they understand that they need to innovate and have even acquired some companies with expertise in alternative fuels. It makes me feel optimistic that they're not just a conventional diesel company stuck in their ways.

At SMS Equipment, we have become the experts at deploying and supporting these technologies and ensuring customers understand the technology and its requirements. We assist customers so they can make the best choices for their operations.