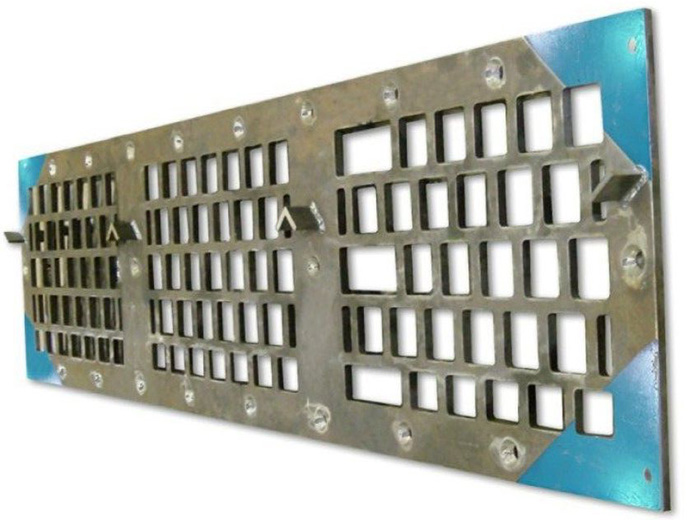

Shovel Bucket Components

Latch Bars, Latch Levels and Inserts including Dutchman

Latchbar with replaceable wear inserts reduce change-out and downtime on rope shovels. The latchbar utilizes replaceable wear inserts designed from JADCO QT PLUS material to better serve rebuild schedules as well as provide a superior material for longer life with the ease of quick replacement.

Features:

- Easier to replace or repair worn areas compared to replacing entire bar

- Increases shovel availability

- Safety improvements from handling smaller components

- Reduces need for adjustments and “shimming”

- Available for all types/OEM’s rope shovels.