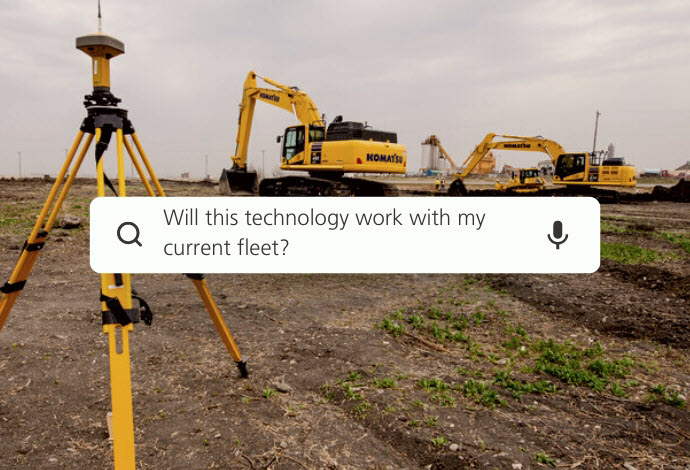

Getting machine control to work with a multi-vendor fleet is one of the most common query topics we see at SMS Equipment, so we decided to take that on this month. In this edition of Experts Corner, we tapped the expertise of Jeff Martin, SMS Equipment Smart Construction Sales Representative, who has worked with equipment control systems for 25 years. In this interview, he shares his insights on the technology landscape, the challenges, and how surprisingly simple it is to manage a mixed fleet from a single point of control.

-

New Equipment SolutionsFrom top brands like Komatsu and Takeuchi, we have new equipment for all your project needs. Discover our range of solutions all backed by our commitment to your success.Pre-owned Equipment SolutionsYou don’t have to buy new to get the job done right. We’re proud to offer pre-owned equipment from some of the world’s leading brands.RentalsAttachments of Every TypeWhether you’re looking for concrete pulverizers or harvesting heads, we’re proud to offer a complete range of attachments that meet your needs — as well as your standards.Promotions

-

Buy Parts OnlineYour source for aftermarket and OEM parts in Alaska.

We provide support for all areas of your equipment, including powertrain, hydraulic systems, lighting, operator environment, undercarriage, electrical systems, cooling systems and more.AttachmentsSMS Equipment holds a unique position in the industry as a one-stop supplier of the most complete range of attachments for your equipment. We offer only world renowned brand names that meet your standards of reliability and productivity.UndercarriagesSMS Equipment brings you a practical management approach to ensure you achieve the best performance and durability from your undercarriage components.Ground Engaging SolutionsEven the harshest construction and mining conditions are no match for our ground engaging tools and parts. Optimize your operation with wear parts designed to endure, saving you both time and money.Promotions -

Maintenance & Repair SolutionsOur range of maintenance and repair services will help you quickly get back on track. Whether emergency repair or preventative maintenance, in-shop or on-site, we will help keep your equipment working exactly as it should.RentalsPromotions

-

News & ResourcesStay ahead by being in the know with SMS Equipment news and resources. Discover trends, expert insights and latest developments that affect you and your business.

-

CareersAt SMS Equipment, we’re more than machines. Join our team of world-class specialists and build your career with us. Explore our open positions near you and across the country.Branch LocationsConnect with us and explore the possibilities. Visit us at any of our branch locations across Canada and Alaska or give us a call. We look forward to hearing from you.About UsThe right partnership makes everything possible. See what sets us apart as a collaborative growth partner committed to your success with comprehensive solutions unique to your operation.News & Resources